This standard is a revision of ANSI/ASQC Z,. “Sampling Procedures and Tables for Inspection by. Attributes.” Beyond editorial refinements, only the. Know the switching rules for ANSI/ASQ Z Categorize the various sampling plan systems in terms of lot-by-lot, continuous production, attributes or variables. ANSI/ASQ Z Sampling Procedures and Tables for Inspection By. Attributes The FDA recognizes ANSI/ASQ Z as a General consensus standard.

- Ansi/asq Z1.4-2008 Pdf Free Download

- Ansi Asqc Z1.4 2008 Pdf Format

- Ansi Asqc Z1.4 2008 Pdf Fillable

- Ansi Asqc Z1.4 2008 Pdf Standard

- Ansi/asq Z1.4-2008 Pdf

Ansi asq z1.4-2008 pdf March 28, 2020 admin Medical Leave a Comment on ANSI ASQ Z1.4-2008 PDF ANSIASQZSampling Procedures and Tables for Inspection by Attributes- ANSI/ASQ Z Sampling Procedures and Tables for Inspection. ANSI ASQC Z1.4-2008 PDF Apr 21, 2020 Sex by admin This standard is a revision of ANSI/ASQC Z. “Sampling Procedures and Tables for Inspection.

| Author: | Daisida Kigazuru |

| Country: | Turkmenistan |

| Language: | English (Spanish) |

| Genre: | Photos |

| Published (Last): | 21 June 2007 |

| Pages: | 318 |

| PDF File Size: | 9.90 Mb |

| ePub File Size: | 4.63 Mb |

| ISBN: | 124-2-72622-826-4 |

| Downloads: | 85871 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Brara |

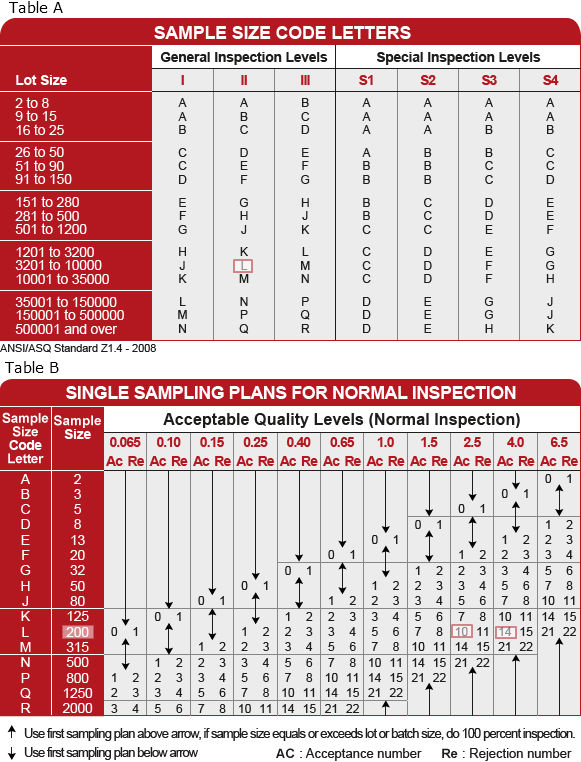

General Inspection Level II, Normal, shows that for a lot size of 20, a sample size code level of M corresponds to a sample size of aeqc As the voice of the U. Another consideration is the percentage of contaminated units per lot. Use double sampling plan above or alternatively use code letter D.

Ansi/asq Z1.4-2008 Pdf Free Download

ANSI/ASQ Z– (R): Sampling Procedures and Tables for Inspection by Attributes | ASQ

I hope this helps. Under multiple sampling, the procedure shall be similar to that speci?

Discontinue Inspection Under Zz1.4-2008. Values given in the table above are based on the Poisson distribution as an approximation to the binomial distribution See The results will be used to identify enhancement opportunities to our database and identifying improvements to the current and more frequent processes.

These plans are intended primarily to be used for a continuing series of lots or batches. Table X-D—Tables for sample size code letter: The team will use a system form in Metastorm to capture activities throughout the day.

ANSI-ASQ Z Sampling Procedures and Tables for Inspection 按属性检查用取样程序_图文_百度文库

Norma ANSI/ASQ Z1.4-2008.

Table I shall be used to? The supplier may be required at the discretion of the responsible authority to inspect every unit of the lot or batch for designated classes of nonconformities. An American national Standard implies a consensus of those zsqc concerned with its scope and provisions.

In general, the function of such classi? The operating characteristic curves of scheme performance are based on the use of limit numbers in 1z.4-2008 to reduced inspection and are approximately correct when the limit numbers for reduced inspection are not used under Option 8.

ANSI/ASQ Z1.4–2003 (R2013): Sampling Procedures and Tables for Inspection by Attributes

By smaller, it is less than 1 standard deviation from the data that has been detected. Since you have no previous data and you are getting 5 samples an hour from each employee, assuming a 7 hour workday, taking out lunch and two breaksthat will give you approximately 35 samples a day.

The responsible authority shall determine whether normal or tightened inspection shall be used on reinspection and whether reinspection shall include all types or classes of nonconformities or only the particular types or classes of nonconformities which caused initial rejection.

Particularly with respect to microbial testing the number of samples are much lower. It may be a single article, a pair, a set, a length, an area, an operation, a volume, a component of an end product, or the end product itself. Now, you will probably want to extend this out another three weeks so that you have an idea of what happens over a month. They show the average outgoing quality limits for scheme performance when using single sampling.

Four additional special levels: Steven Walfish Secretary, U. These rules are designed to encourage suppliers to have process averages consistently better than the AQL.

D Acceptance Quality Limits normal inspection 1. How can we improve our incoming inspection process? However, we run a variety of tests, including microbial and heavy metal testing. Rejection in an acceptance sampling sense means to decide that a batch, lot or quantity of product, material, or service has not been shown to satisfy the acceptance criteria based on the information obtained from the sample s.

The extent of nonconformance of product shall be expressed either in terms of percent nonconforming or in terms of nonconformities per hundred units.

Tag: Z1.4:2008

If that is not possible or practical, then percent inspection using a quick, inexpensive, and effective method permits you to avoid uncertainties with sampling. These tests are very costly. Normal, tightened or reduced inspection shall continue unchanged on successive lots or batches except where the switching procedures given below require change. The operating characteristic curve for unquali?

An AQL for a group of nonconformities may be designated in addition to AQLs for individual nonconformities, or subgroups, aqc that group. Tables VI and VII give process levels for which the probabilities of lot acceptance under various sampling plans are 10 percent and z1.4-20008 percent respectively. If the cumulative number of lots not accepted in a sequence of consecutive lots on tightened inspection reaches 5, the acceptance procedures of this standard shall be discontinued.

A sample consists of one or more units of product drawn from a lot or batch, the units of the sample being selected at random without regard to their quality.

The following two de? Can I get further explanation of how one would justify that less discrimination is needed? Apparently, you are able detect the container contamination prior to filling them, or are able to andi the effect of the contamination on the final product. Table X-E—Tables for sample size code letter:

Most 10 Related

ANSIASQZSampling Procedures and Tables for Inspection by Attributes- ANSI/ASQ Z Sampling Procedures and Tables for Inspection by. This e-standard is a very minor revision of ANSI/ASQ Z (R), also referred to as ANSI/ASQ Z ANSI/ASQ Z Sampling Procedures and Tables for Inspection By. Attributes The FDA recognizes ANSI/ASQ Z as a General consensus standard.

| Author: | Tajas Akinojin |

| Country: | Netherlands |

| Language: | English (Spanish) |

| Genre: | Politics |

| Published (Last): | 3 November 2015 |

| Pages: | 266 |

| PDF File Size: | 2.16 Mb |

| ePub File Size: | 20.58 Mb |

| ISBN: | 476-5-23161-145-7 |

| Downloads: | 29468 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Vudoshakar |

However, Inspection Level I may be speci? If you use one of the special sampling plans based on the cost of the test, it is helpful to calculate the actual AQL and Limiting Quality LQ using the following formulas. The correct use of these tables is discussed further. The frequency of hourly entries and length of period to capture the data can be adjusted to accommodate the resulting sample size.

These tests are very costly.

ANSI/ASQ Z – Sampling Procedures and Tables for Inspection by Attributes

Justification of a sampling plan is based on risk and a sampling plan can be justified based on the cost of the test, assuming you are willing to take larger sampling risks. A departure of a quality characteristic from its intended level or state that occurs with a severity sufficient to cause an associated product or service not to satisfy intended normal, or foreseeable, usage requirements.

It is expected that the product quality level will be less than the AQL to avoid excessive non-accepted lots. Sampling The views and opinions expressed in this paper are those of the individual author and should not be attributed to any company with which the author is now or has been employed or affiliated.

Less discrimination means that the actual Acceptable Quality Level AQL on the table underestimates the true AQL, as the sample size has been reduced from the table-suggested sample size i.

awq If the product is not sensitive you can test samples from the beginning, middle and end of filling. ASQC Q contains sampling plans that have been calculated on this basis and therefore provide a more accurate set of tables for these situations.

We want to ensure that we are receiving clean containers to package our products. With anwi sampling plans, be many sampling sequences to there are three different conclusions: The lot or batch size is the number of units of product in a lot or batch.

Tag: Z1.4:2008

The AQL alone does not describe the protection to the consumer for individual lots or batches, but more directly relates to what is expected from a series of lots or batches provided the provisions of this standard are satis?

Sampling Plan Types Three types of sampling plans are provided: But prior to doing that, we certified our suppliers by going to their facility and performing a process audit to make sure that the process was meeting our requirements. This should give you enough information to get an estimate of what is done for a week. If my AQL is 0.

Another approach is using light to illuminate the contamination, such as a black light UVA. When appropriate, the number of units in the sample shall be selected in proportion to the size of sublots or subbatches, or parts of the lot ajsi batch, identi? Sampling Procedures and Tables for Inspection by Attributes.

Defect categories are divided based on criticality to product quality attributes. There are many references available that will assist you in the selection of an appropriate sampling plan based on your desired sampling risk tolerance levels. Inspection under the provisions of this standard shall not be resumed until corrective action has been taken.

Not for Resale Multiple? We have a number of different defects that fall z11.4-2008 an AQL of 1. Usually the administrative dif? What we did was to inspect at the beginning and the end of each tape. If you can determine the source or sources of the contamination, the best fix is to remove the cause. My anis question is if I have a batch that passes acceptance sampling but at a subsequent downstream process a defect being inspected z1.4-22008 by the upstream acceptance sampling inspection is found how do I determine if the lot is acceptable?

If I have one lot that fails Acceptance sampling and I am trying to bound the issue is it suitable to bound it to the one affected lot if the lot before and after pass or do I need to carry out additional sampling. To construct an OC curve, one needs to know the sample size n and the number of defects c one is willing to accept. Apparently, you are able detect the container contamination prior to filling them, or are able to detect the effect of the contamination on the final product.

Ansi Asqc Z1.4 2008 Pdf Format

The standard divides inspection levels into two main z14.-2008 If all incoming lots are assumed z11.4-2008 be at the same process average and if the nonconforming items that z1.4-2080 discovered and replaced by conforming items during sample inspection are ignored, it will be found that both the set of accepted lots and the set of non-accepted lots will have the same long run average quality as the original set of lots submitted for inspection.

Ansi Asqc Z1.4 2008 Pdf Fillable

The number of sample units inspected shall be equal to the sample size given by the plan. You can download and open this file to your own computer but DRM prevents opening this file on another computer, including a networked server.

Z1.4:2008 inspection levels

Operating characteristic curves and other measures of performance presented in this standard are of two types. When normal inspection is in effect, reduced aq shall be instituted providing that all of the following conditions are satis? For example, my lot size is which means, under general inspection level II, the sample size would be 80 code J.

The packaging defects can be classified into three major categories: General Inspection Level II, Normal, shows that saq a lot size of 20, a sample size code level of M corresponds to a sample size of If you can assume that the data collected is representative of all ass, then you should be O. Use single sampling plan above or alternatively use code letter D.

Ansi Asqc Z1.4 2008 Pdf Standard

A schematic diagram describing the sequence of application of the switching rules is shown in Figure 1.

Ansi/asq Z1.4-2008 Pdf

Note, the sampling plan consists of a sample size and acceptance criteria andi particular AQL. If they want to know if individual units within the lot are acceptable — based on all criteria that is considered acceptable, then the tally of all defects found is correct. Instead, these defects are added based on the product attribute tablet count, closure, etc. Some are faster than others, and some are non-destructive.

The AQL is the quality level that is the worst tolerable process average when a continuing series of lots is submitted for acceptance sampling. AQL values of Different AQLs may be designated for different types of defects critical, major, and minor. Inspection of incoming lots whose quality levels vary around a?